Mastery in Processing: From Packaging to Painting, the Art of Processed Wood

At the heart of our artisanal process of creating custom-made wooden floors, every stage of processing is treated with extreme attention to detail, from the choice of materials to the final delivery. We start with the sampling, a careful selection of colors and the development of innovative formulas, allowing you to replicate various colors, even of different materials, to create custom floors that respond exactly to the requests of our customers. Planing and moulding are key steps where, through manual and mechanical techniques, we give floors a characteristic aged appearance, enhancing the natural peculiarities of wood such as knots and veins. The brushing further accentuates the veining of the wood, eliminating the softest parts and giving the floor a unique and distinctive appearance. The spray painting, made with high pressure guns, ensures a soft finish to the touch but extremely durable, ensuring that the floor maintains its beauty over time. Finally, the packaging, both of the floors and the baseboards, is done with care and precision, ensuring that each element arrives at its destination in impeccable condition, ready to enrich the spaces with elegance and style. Our dedication to transforming wood into livable works of art is evident in every step, reflecting the uniqueness of each project we make.

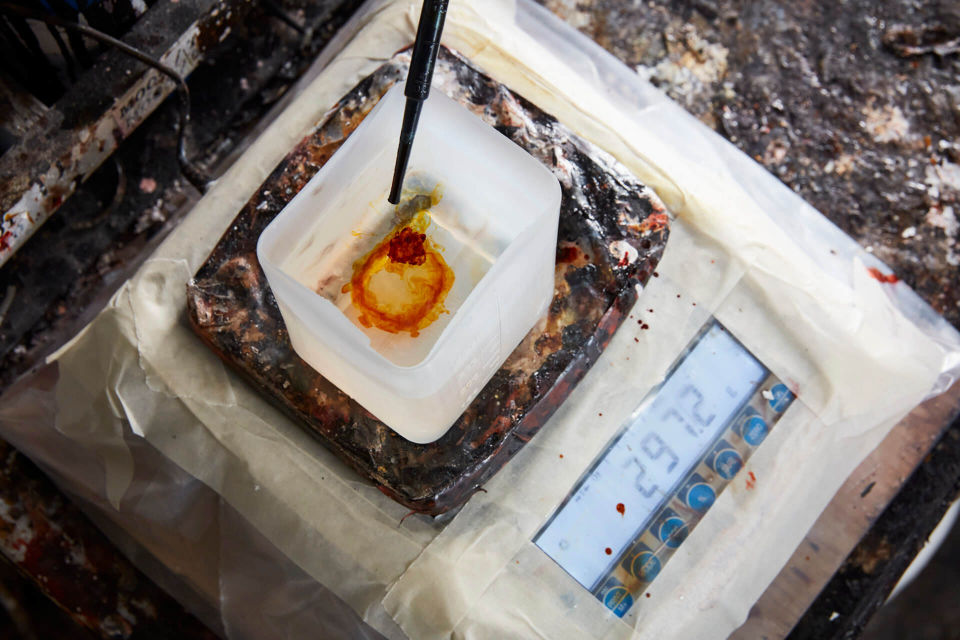

Sampling

Through the careful study of color combinations and the research and development of new formulas, the operator replicates colors of other materials to create the custom-made floor.

Planing

Through the use of electric or manual planers, the operator gives the floors an aged style, highlighting the various characteristics of the wood (knots, flames, cracks).

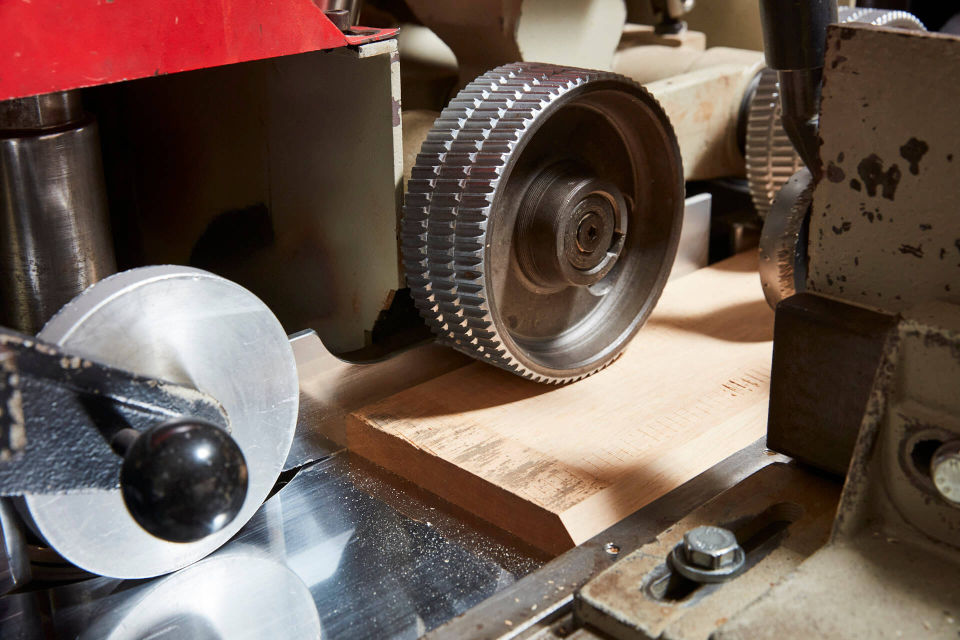

Moulding

The use of this machinery allows you to create custom profiles starting from a simple piece of wood: baseboards, stair nosing, joint or any solid profile is made with this machinery.

Brushing

This is one of the first processes that is carried out on the floors because it serves to emphasize the veining of the wood and to remove the softer parts. By pressing iron brushes and Teflon the operator can decide the degree of brushing.

Painting

We realize only spray painting through the use of high pressure guns: this allows to obtain a soft to the touch effect but resistant at the same time. Following well catalogued procedures and recipes, the operator creates the floor chosen by the customer.

Packing floors

Work step in which the operator performs the final quality control and through special machinery packs the material and prepares it for shipment.

Packing baseboard

Work step in which the operator performs the final quality control and through special machinery packs the material and prepares it for shipment.